|

According to a report conducted by ARUP, around 75% of the world’s population will live in cities by the year 2050. Mass transportation megatrends will have a global impact in terms of mobility and transportation infrastructure. High-speed rails play an important role in urbanization by reducing travel times for commuters traveling from city to city. Meanwhile, advancements in sensors and wireless communication technologies have led to continuous data collection in high-speed railway systems. This enables high-speed rails to maintain operational efficiency for its mechanical and electrical conditions to provide reliable and safe transportation service.

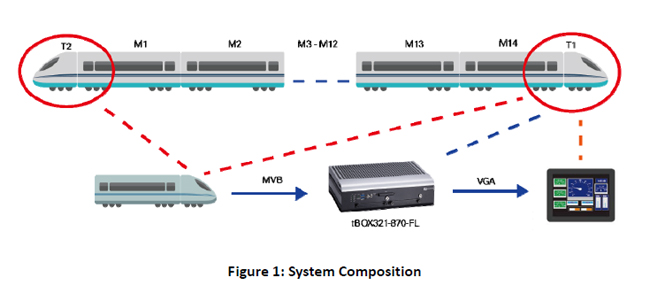

One of our customers adopted the tBOX321-870-FL as an intelligent gateway in order to connect a wide range of mechanics, systems, and environments while using on-board sensors to measure parameters such as temperature, shocks, tilts, and humidity. The tBOX321-870-FL is an ideal EN 50155 system for providing real-time movable condition monitoring, allowing for early detection and diagnosis of problems which can result in improved reliability, safety and efficiency.

Industry Trend

As interest in high-speed rail lines surges, the number of countries running these trains is expected to nearly double over the next few years, according to research from the Worldwatch Institute. The increase in high-speed rail availability is due largely to its reliability, ability to cover vast geographic distances in a short time, allowing connections to once-isolated regions, and the diminishing appeal of air travel- which is becoming more cumbersome because of security concerns.

Additionally, the high-speed rail industry has addressed some technical problems and started to develop rapidly around the world. As many nations are trying to increase the running speed of high-speed trains, the other aspect that many people find interesting is that high-speed rail systems are becoming intelligent.

The next-generation of rail-certified transportation systems will require major advances in related technologies, especially in Industrial Internet of Things (IIoT) related applications like sensors and wireless connectivity. Intelligent rail transportation is a decision support, asset performance and monitoring solution that enables operators to evaluate the safety, condition and performance of the train in real-time, based on the advancements of sensors, systems and data analysis.

Infrastructure Features

High-speed trains operate significantly faster than traditional trains and the major challenge is how to improve the safety and reliability when operating at such high speeds. The goal of our customer’s project was to build a high-speed railway intelligent transportation system with real-time on-board condition monitoring, data transmission and data analysis. The ultimate purpose was to evaluate the customer’s high-speed railway safety and support maintenance schedules in order to improve the train’s reliability.

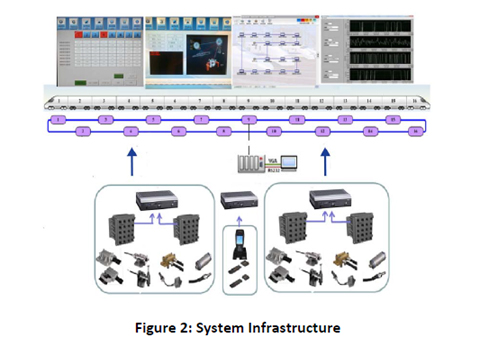

The diagram below demonstrates how the customer integrated several transportation-certified solutions into a high-speed railway infrastructure, including networks and devices such as on-board sensors, data transmission, intelligent railway gateway devices and human machine interfaces (HMI) for complete connectivity.

This system is comprised of three layers.

- Sensor Layer: There are a multitude of sensor types used in railway condition monitoring for analyzing different aspects of structures, infrastructure, and machinery. Sensor devices also quantify environmental statuses such as temperature and humidity, which can be combined with the measurements from other systems. The sensor layer can obtain information for the following:

(A) General train information: Position, velocity, etc.

(B) Track information: Acceleration, temperature and stress information

(C) Power system: Voltage, transformer, inverter and brakes

(D) On-board equipment: Air conditioning, doors, temperature, humidity and pressure

(E) Public security: Smoke detectors

- Network Layer: The network layer is comprised of three sub-networks. They are railway network, ground-railway communication layer and ground fiber layer. The railway network consists of the Multifunction Vehicle Bus (MVB) inside each train cart and the Wire Train Bus (WTB) to connect the MVB parts with the train control system. The network layer has the following functions:

(A) General data acquisition and data storage

(B) Real-time data analysis and diagnosis

(C) Alert management

- Data Analysis Layer: The data analysis layer features a railway intelligent gateway device, which relays information by wirelessly connecting to a ground data center. Axiomtek’s railway intelligent gateway, the tBOX321-870-FL, is the central unit of the railway network and it is designed to analyze the data acquired from the sensor layer. It can process the data from running trains at high speed, diagnose the operational status of multiple trains, send alerts/warning messages to the conductor, and provide wireless communication between the train control system and ground data centers. The tBOX321-870-FL can help conductors operate the trains in a reliable and safe manner.

Ground data centers manage important operational data for devices used in high-speed railway applications. Having a ground data center analyze information obtained from railway intelligent gateway devices can be used to detect maintenance requirements in order to minimize downtime. This information can be used to request maintenance based on the prediction of system failure rather than running to a standard schedule or being requested following an actual failure. The data analysis layer has the following functions:

(A) Display operating information (B) Show alert/warning messages

(C) Troubleshooting guide

(D) Troubleshooting derivation

(E) Knowledge base input and expansion

System Design Features

The tBOX321-870-FL is a robust railway PC that supports Intel® Core™ i7-3517UE (up to 2.8 GHz) or Intel® Core™ i3-3217UE (1.6 GHz) processors. The tBOX321-870-FL adopts an onboard processor and onboard DRAM which greatly reduces the impact of vibration and shock, making it an ideal solution for rugged railway applications. The tBOX321-870-FL is certified with EN 50155 / EN 50121 for rolling stock, complies with EN 45545-2 for fire resistance, and features power interruption class S2 for power supply stability- all of which provides the system with the ability to work in various transportation-related applications. This compact railway box computer has an IP40-rated rugged aluminum extrusion and steel case. The railway box PC can operate in mission critical environments with an extended temperature range of -40°C to +70°C. This application-ready railway PC is suited for applications such as mobility control units, passenger information systems, video surveillance and more. The tBOX321-870-FL is a robust railway PC that supports Intel® Core™ i7-3517UE (up to 2.8 GHz) or Intel® Core™ i3-3217UE (1.6 GHz) processors. The tBOX321-870-FL adopts an onboard processor and onboard DRAM which greatly reduces the impact of vibration and shock, making it an ideal solution for rugged railway applications. The tBOX321-870-FL is certified with EN 50155 / EN 50121 for rolling stock, complies with EN 45545-2 for fire resistance, and features power interruption class S2 for power supply stability- all of which provides the system with the ability to work in various transportation-related applications. This compact railway box computer has an IP40-rated rugged aluminum extrusion and steel case. The railway box PC can operate in mission critical environments with an extended temperature range of -40°C to +70°C. This application-ready railway PC is suited for applications such as mobility control units, passenger information systems, video surveillance and more.

|