|

|

| |

| |

|

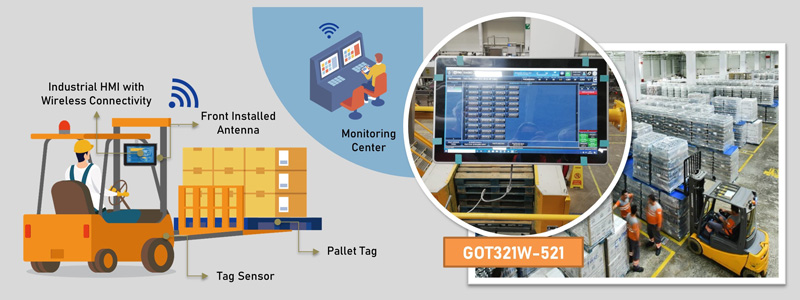

Real-time warehouse management by Human-Machine Interface

|

|

| |

For large distilleries that produce a variety of alcoholic beverages, managing the warehouses and logistics is a challenging task; in such a fast-paced workplace, executives turn to Human-Machine Interface (HMI) for more efficient management. The HMIs enable the visualization of the warehouse operation status, and the workers can quickly identify the location of the pallets and ensure pick up the right goods and drop them off at the correct locations with connected tags and sensors.

|

|

|

| |

|

The customer was looking for a 21.5-inch all-in-one touch panel PC to build a Human-Machine Interface for pallet control in distilleries and warehouses. The industrial-grade panel PC has to support the high-performance Intel® Core™ processor and be equipped with a multi-touch projected capacitive widescreen. Since the touch panel PC is used for alcoholic beverage processing, an IP65-rated front bezel is required to protect screens from liquid splashes. Moreover, it needs to support a panel mount for seamless integration into the forklifts.

|

| |

| Main Requirements |

- 21.5" FHD 1920x1080 TFT LCD panel with multi-touch

- Fanless design with high-performance Intel® CoreTM processor

- High quality and product long-life cycle

- IP65/NEMA 4-rated front bezel for harsh environments

- Supports panel mount

|

| |

|

|

|

The heavy-duty touch panel PC ensures stable operation in the warehouse

|

|

Axiomtek has proposed its GOT321W-521, a 21.5-inch multi-touch FHD TFT expandable panel computer, powered by the Intel® Core™ i7/i5/i3 processor, Intel® Pentium® Gold or Celeron® processor with the Intel® H310 chipset. The slim-type industrial panel PC adopts an FHD TFT LCD display with 10-point multi-touch, 250 nits brightness, and 178°/178° wide-viewing angle. It also scales with IP65/NEMA 4-rated protection against water and dust. The rugged touch panel PC features rich I/O including four USB ports, two LAN ports and two COM ports. With an M.2 Key E slot, the panel PC can connect with other field-site devices to receive real-time data. Axiomtek has proposed its GOT321W-521, a 21.5-inch multi-touch FHD TFT expandable panel computer, powered by the Intel® Core™ i7/i5/i3 processor, Intel® Pentium® Gold or Celeron® processor with the Intel® H310 chipset. The slim-type industrial panel PC adopts an FHD TFT LCD display with 10-point multi-touch, 250 nits brightness, and 178°/178° wide-viewing angle. It also scales with IP65/NEMA 4-rated protection against water and dust. The rugged touch panel PC features rich I/O including four USB ports, two LAN ports and two COM ports. With an M.2 Key E slot, the panel PC can connect with other field-site devices to receive real-time data.

|

| |

|

Real-time pallet management via a Human-Machine Interface

|

| |

|

|

One of the most pain points in warehousing is finding the location of finished goods that have been stored in the warehouses. In this solution, the customer installed the tag sensors, antenna and Axiomtek’s 21.5-inch high-performance GOT321W-521 on the forklifts to identify different pallet tags. Through the pallet control HMI, the operators can easily identify a pallet storage location and pick it up or drop it off at the designated location. Meanwhile, it will also send the inventory data back to the monitoring center. Overall, the solution optimizes inventory management and makes the work of forklift operators more efficient. It speeds up the delivery to distributors and helps increase profits.

|

| |

| System Configurations of the GOT321W-521 |

- 21.5" FHD 10-point multi-touch projected capacitive widescreen

- LGA1151 socket Intel® Core™ i5 processor (code name: Coffee Lake)

- 8GB DDR4-2400 system memory

- One 128GB SATA SSD for storage

- IP65/NEMA 4-rated front bezel

- 250 nits of brightness

- Supports WLAN module and antenna

- Two LAN, four USB, two COM, one HDMI, one DisplayPort, and one VGA

- Panel mount

- Built-in speakers and swappable hard drive design

- Supports Windows® 10 IoT operating system

|

| |

|

|

| |

|

As one of the leaders in industrial PC, Axiomtek possesses rich know-how in touch panel PC. Axiomtek provides touch panel PCs in various IP ratings, display sizes, resolutions, aspect ratios, and CPU levels. Customers can choose the system that best meets their needs and optimize the workflow with it.

“We have a variety of alcoholic beverages, including Raki, Vodka, Kayra, Terra, and red wines; therefore, how to manage these large quantities of beverages through pallet control is a complicated issue in the warehouse. Thanks to Axiomtek, its powerful panel PC shows excellent performance and great integration with the management software. Its quick service response and professional technical support also surprised us,” said the project manager from the customer.

|

| |

|

|

|